|

|

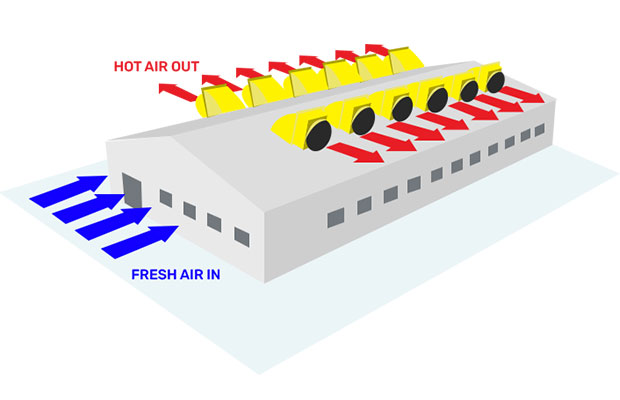

Professional Solution for Heat, Dust and Smoke

|

- Exhaust Fan System

|

By using negative pressure ventilation system, fresh air can be imported into a factory within 30 seconds to 1 minute. At the same time, it can achieve cool and comfortable feeling according to required wind speed. Its cooling, ventilation and exhaust effect can reach 90-97%.

According to scientific research to date at current international level, negative pressure ventilation system is the best solution for elimination of sultry heat, smoke, smell, exhaust gas and dust in the factory. It is energy saving and economical investment. |

|

| |

.jpg) |

|

|

| Floorplan |

|

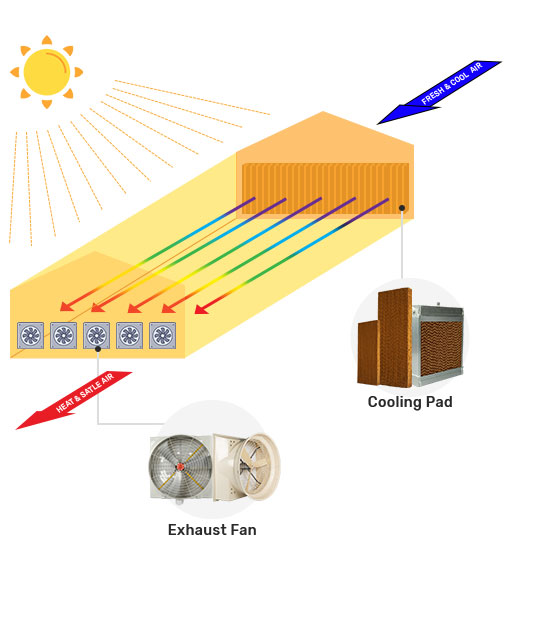

Professional Air Quality Solution

|

- Cooling Pad System

|

| The room will be sealed, a cooling pad will be installed at one end, at the other end an Exhaust Cone Fan will take place. Hot air will be exhausted by the exhaust fan from the factory forming a negative pressure effect, water molecules of the cooling pad decompose heat from the sun when air passes through from outside the factory, cool water vapor will flow into the factory to increase humidity of the air and reduce the room temperature, thereby creating a cool and comfortable working environment. The system can maintain room temperature between 26 to 29°C. Air will constantly re-circulate indoor and outdoor, moreover oxygen content will increase in the air. |

|

| |

|

|

|

|

|

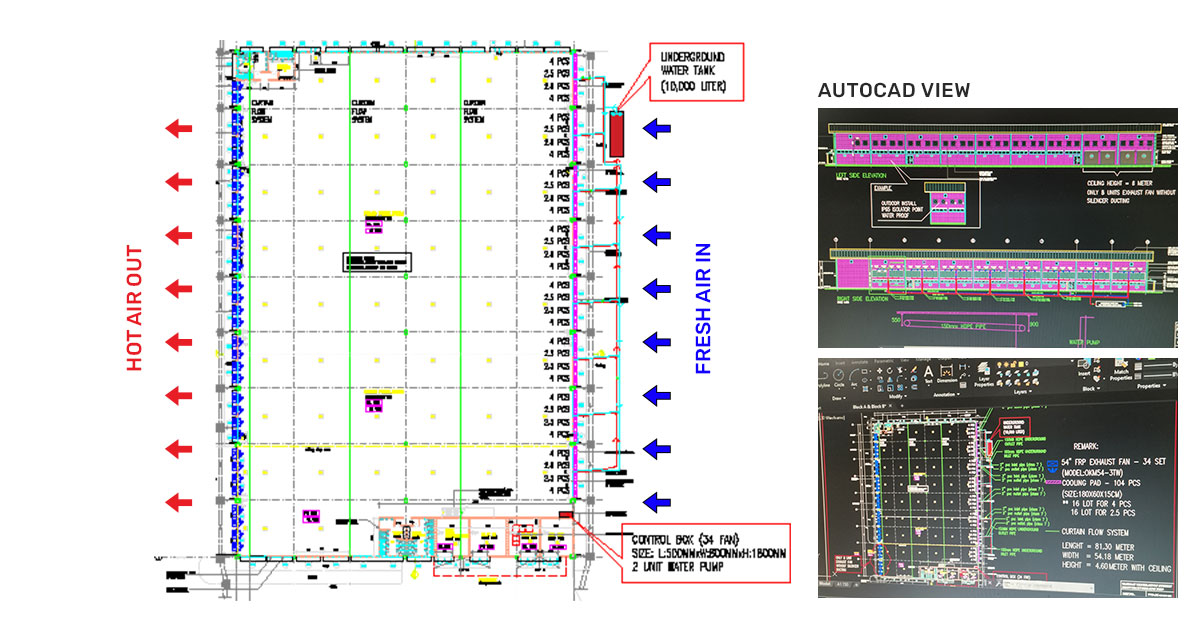

| Floorplan |

|

| |

| |

Professional Ventilation Solution

|

- Cooling Machine System

|

| The cooling machine is simply a combination of a fan and a cooling pad. We name it “Positive Pressure System”, its core is the “cooling pad”, and it can reduce 5-7 ° C without any air compressor, chiller, nor copper-free tube. It is an environmental friendly and energy saving product. |

| |

|

| |

.jpg) |

|

.jpg) |

| Floorplan |

|

Side View |

| |

| |

| |

|